Axle Weighbridges

Dynamic & Static Vehicle Weighing Systems

Midweigh supplies, installs and services axle weighbridge systems for accurate vehicle weighing across the UK. Our range includes dynamic weighbridges for in-motion weighing and static weighbridges for stationary axle weight measurement, both designed to ensure compliance with statutory weight regulations for all types of commercial vehicles.

With over 50 years of expertise in the weighing industry, Midweigh provides complete weighbridge solutions including site survey, civil engineering consultation, installation, commissioning, calibration and ongoing maintenance support. All systems are supplied with certified calibration and full technical documentation.

Dynamic Axle Weighbridge

The Midweigh 825 Dynamic Weighbridge is a British-made, high-quality axle weighbridge system designed for in-motion vehicle weighing. Vehicles drive over the weighbridge at controlled speeds (typically 3-5mph) and individual axle weights are captured automatically, providing total vehicle weight without the need to stop.

Powder-coated for longevity and durability in harsh outdoor environments, the system includes a full internal fleet management program installed on every system. The Cardinal 825 Indicator provides intuitive operation with data logging, printing capabilities and PC connectivity for record keeping and reporting.

Dynamic axle weighbridges are ideal for high-throughput operations including logistics depots, waste management facilities, quarries and agricultural sites where rapid vehicle weighing is essential. Midweigh also provides full service support for Central Weighing Supaweigh 3000 and 4000 axle weighbridge systems.

Key Features:

- In-motion weighing - no need to stop vehicles

- High accuracy despite vehicle movement

- Integrated fleet management software

- Weather-resistant construction

- Suitable for 2, 3 and multi-axle vehicles

- Data logging and reporting capabilities

Static Axle Weighbridge

The Midweigh Weigh-In Static Weighbridge is designed for weighing 2-axle rigid vehicles in static mode, where each axle is positioned on the weighbridge platform and weighed individually whilst stationary. Weights are displayed on the indicator and can be recorded manually or via an optional printer for documentation and compliance purposes.

Built to the same high standards as our dynamic systems but utilising lower capacity load cells and simplified instrumentation, the static weighbridge offers a more economical solution for operations where in-motion weighing is not required. This makes it ideal for smaller sites, lower volume operations or applications where vehicles can stop for weighing without disrupting workflow.

Key Features:

- Economical alternative to dynamic systems

- High accuracy static weighing

- Simple, reliable operation

- Optional printer for weight tickets

- Robust construction for outdoor use

- Lower running and maintenance costs

Installation & Commissioning

Midweigh provides complete installation services for axle weighbridge systems including civil engineering works, foundation construction, weighbridge installation, electrical connections and system commissioning. Our experienced engineers ensure weighbridges are installed to precise specifications and fully calibrated to provide accurate, compliant weighing from day one.

We work with clients to determine the optimal weighbridge location, traffic flow considerations and any site-specific requirements. Full site surveys are conducted prior to installation and we liaise with civil engineering contractors where ground works are required.

Calibration & Servicing

Regular calibration is essential to maintain weighbridge accuracy and ensure compliance with weights and measures regulations. Midweigh provides certified calibration services using traceable test weights, with calibration certificates issued for every system tested. We offer annual or bi-annual calibration schedules to suit operational requirements.

Our breakdown call-out service ensures rapid response to any weighbridge issues, with our commitment to return your system to full service in one visit. We also offer scheduled maintenance contracts and Golden Warranty packages providing comprehensive parts and labour coverage.

Applications & Industries

Axle weighbridges are used across numerous industries where vehicle weight verification is required for compliance, operational efficiency or commercial transactions:

- Logistics & Transport: Ensuring vehicles comply with axle weight limits and gross vehicle weight restrictions

- Waste Management: Weighing waste collection vehicles for billing and regulatory reporting

- Quarries & Aggregates: Weighing loaded vehicles for sales transactions and site management

- Agriculture: Weighing grain lorries, livestock transporters, and agricultural vehicles

- Manufacturing: Goods-out weighing for delivery verification

- Recycling: Material weighing for waste streams and recyclables

Axle Weighbridge Installation Gallery

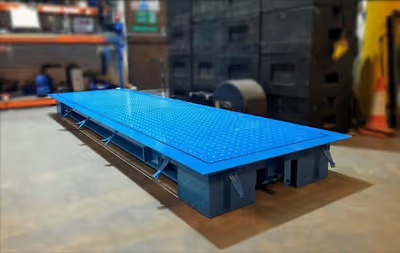

25 Ton Weighbridge (latest design)

Calibration

Axle Weighbridge

Installed Axle Weighbridge

Full Concrete Site Construction

On-Site Deadload Testing

On-Site Deadload Testing

Axle Weighbridge

Driver-Operated Cab High Post, Indicator,

Printer and Display

Dynamic Weighing Instrumentation

Large Scale Display for Drivers

Dynamic Weighing Instrumentation

Driver-Operated Indicator and Printer

Dynamic Weighing Instrumentation

100mm LED Large Scale Display

Dynamic Weighing InstrumentationDiscuss Your Axle Weighbridge Requirements

Get in touch for expert advice on dynamic and static axle weighbridges, installation requirements and ongoing service support. We provide tailored weighing solutions for your specific operational needs.